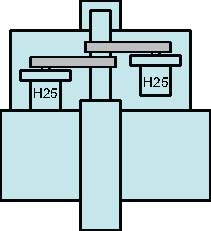

Overview

Container Cranes are a common sight at ports. What's new is their improved automation to ensure higher performance and operator safety.

To ensure higher performance, OEMs install absolute encoders, typically 4 units:

- Each main hoist motor (x2)

- Trolley

- Boom (angle)

OEMs and end-users are depending on the absolute encoders--typically the main hoist encoder positions are compared in software--if there is any difference, the crane will shut down. Likewise, accurate boom angle and trolley position is critical. Errors can result in crane malfunctions or shutdowns.

/XR115.png)