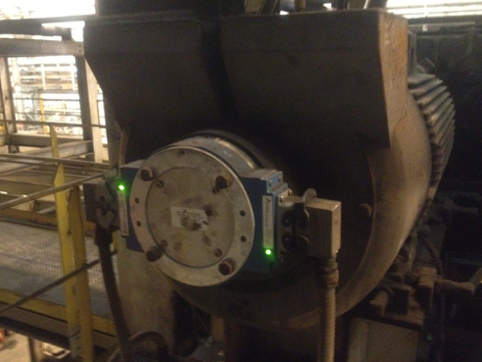

This blog will discuss why magnetic encoders overcome limitations and provide superior reliability in metals applications.

Magnetic Encoder Advantages in Metals Industry Applications

Topics: Metals

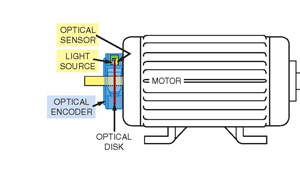

Why Optical Encoders Fail in Metals Industry Applications

This blog will introduce various metals industry encoder applications and discuss typical challenges. These challenges can be grouped into Environmental Challenges and Mechanical Duty Challenges.

Topics: Metals

Metals Encoder Application Challenges

This blog will introduce various metals industry encoder applications and the environmental and mechanical challenges they present.

Topics: Metals

Understanding Metals Industry Position Feedback Devices

Understanding Metals Industry Position Feedback Devices

This blog will introduce the three main types of position feedback devices from a historical perspective and discuss their uses in metals processes.

Topics: Metals

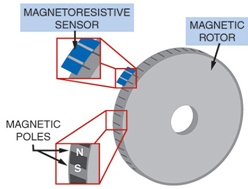

Understanding Metals Industry Speed Feedback Devices

Speed Sensors

The Dictionary.com definition for Tachometer:

[ta-kom-i-ter, tuh-]

any of various instruments for measuring or indicating velocity or speed

So tachometers are speed measurement devices. Their use in the metals industry goes back decades to the development of analog drive control systems.

This blog will introduce the three main types of speed feedback devices from a historical perspective and discuss their uses in metals processes.

Topics: Metals

Understanding Metals Industry Rotary Sensors

They are called many things: tachometers, tachos, tach-generators, pulse generators, resolvers, encoders, incremental encoders, absolute encoders, rotopulsers, selsyns, the list seemingly goes on and on. How does the metals industry electrical professional know what all these devices are and what kinds he has or needs? In the first of a three-part series, this blog will introduce the main metals industry rotary motion sensors, speed and position.

Topics: Metals

What Kills Encoders in Pulp & Paper Mill Environments

Bearings and seals are the main failure items for any encoder in a mill environment today. Lip seals, shaft seals and bearings all have static surfaces in contact with rotating surfaces. Gradually these seal points will wear or break down and allow material to pass into the encoder housing and contaminate optics and short electronics. As bearing surfaces wear, radial movement increases at both seal surfaces, accelerating failure and causing optical path misalignment. Eliminating the bearings and seals from your encoder applications will drastically lengthen the life of your feedback devices.

Topics: Pulp and Paper

Wind Systems Magazine's Q&A with Brian Winter

Wind Systems Magazine interviewed Nidec Avtron Encoders’ Product Manager Brian Winter about encoder trends in the wind industry.

or read it here:

Conversation: Brian Winter

Brian WinterEncoder Product Manager

Nidec Avtron Automation

Topics: Wind Power

How Stacker Cranes Benefit From Absolute Encoders

Overview

Topics: Absolute Encoders

How Truck Mounted Cranes Benefit From Absolute Encoders

Overview

Truck Mounted Cranes are an indispensable tool on many construction sites. The compact dimensions and mobility of the truck allow the crane to be driven to the work site and set into position. Although the crane may appear small on the truck, once the support system and telescopic mast are extended, it becomes an impressive piece of transport machinery. The operating range of the booms on these types of cranes was once much more restricted, but today, PLC controls and absolute encoder technology ensure that the boom can be pushed to its limits.

Absolute encoder technology is used on truck mounted cranes to increase the range and accuracy of positioning the boom, and to increase safety. Absolute encoders are used as part of the safety system that locks the crane automatically before the system reaches critical limits.

Topics: Absolute Encoders