Overview

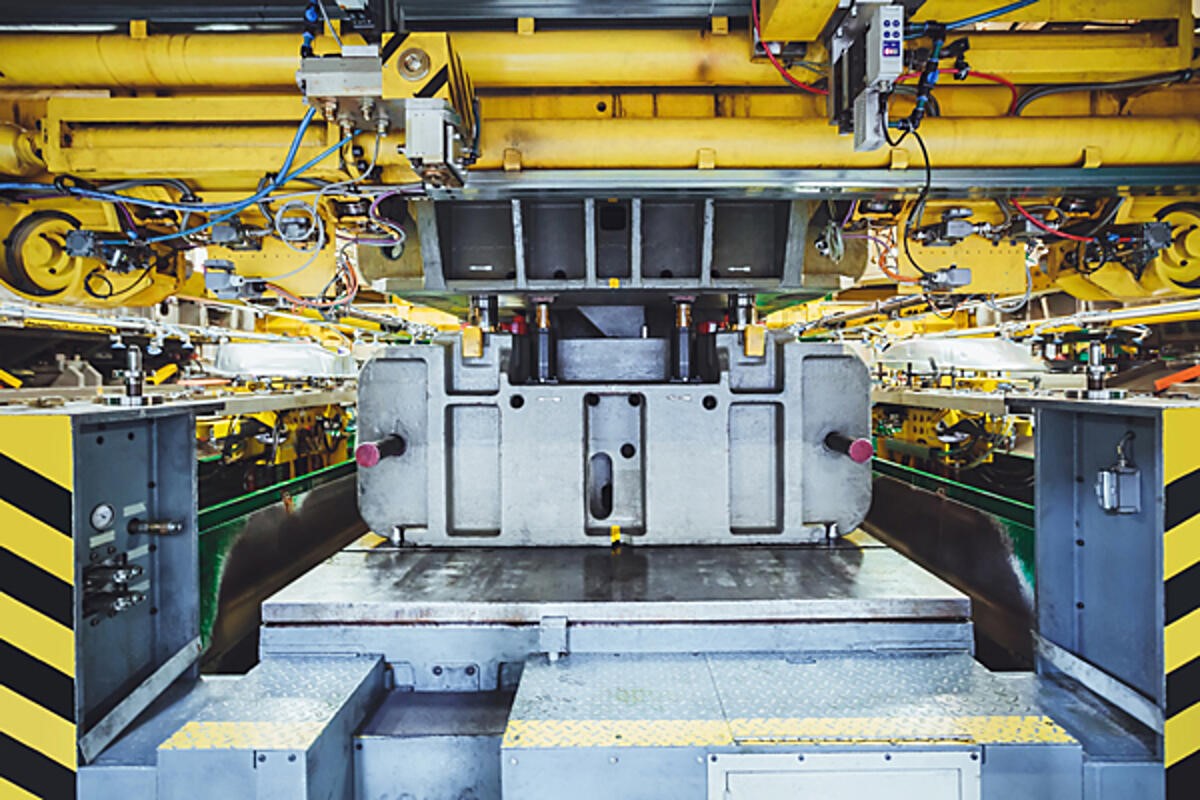

Truck Mounted Cranes are an indispensable tool on many construction sites. The compact dimensions and mobility of the truck allow the crane to be driven to the work site and set into position. Although the crane may appear small on the truck, once the support system and telescopic mast are extended, it becomes an impressive piece of transport machinery. The operating range of the booms on these types of cranes was once much more restricted, but today, PLC controls and absolute encoder technology ensure that the boom can be pushed to its limits.

Absolute encoder technology is used on truck mounted cranes to increase the range and accuracy of positioning the boom, and to increase safety. Absolute encoders are used as part of the safety system that locks the crane automatically before the system reaches critical limits.