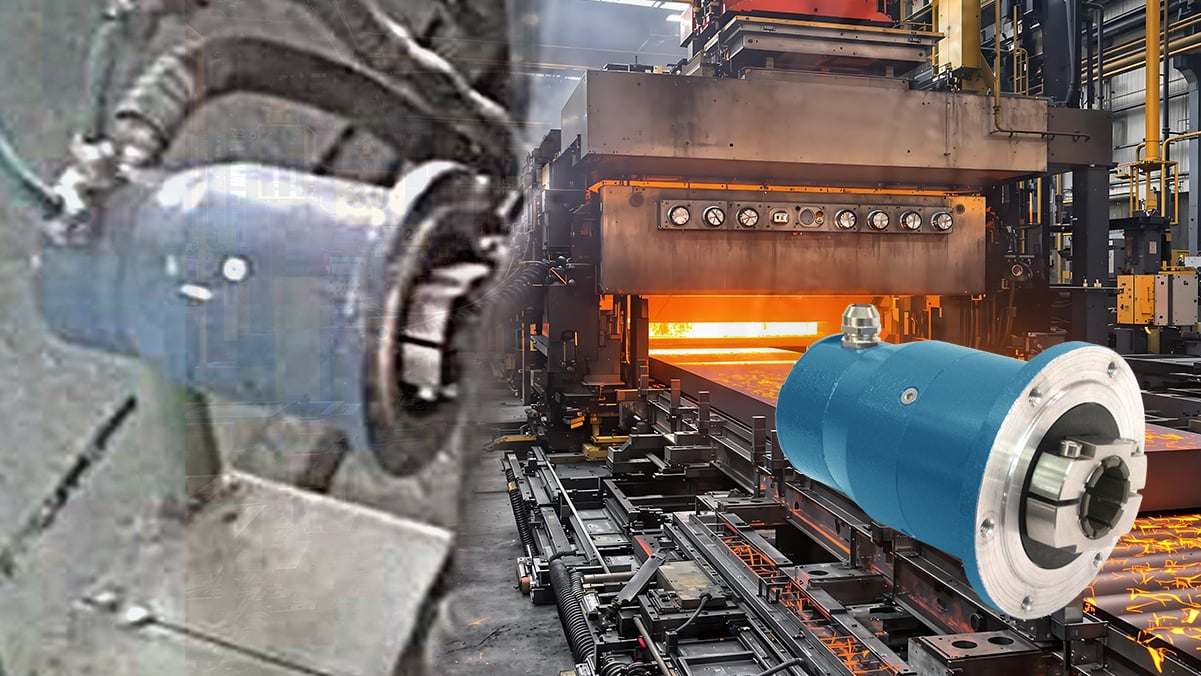

If your facility runs heavy equipment day in and day out, chances are your encoders don’t live an easy life. Steel dust in the air, constant vibration, temperature swings, washdowns, and the occasional shock load are all part of normal operations. In these conditions, not all position encoders are up to the task. Understanding what truly makes an environment “harsh” — and how the right encoder choice can protect uptime — is key for today’s manufacturing leaders.

What makes an industrial environment “harsh” for position encoders?

A harsh environment isn’t defined by one factor alone. It’s the combination of stresses that gradually wear down components. Dust, dirt, oil mist, and metal particles can infiltrate housings and interfere with sensing elements. Moisture from washdowns or outdoor exposure can corrode internals if sealing isn’t adequate. Add in extreme heat, cold, or rapid temperature changes, and materials expand and contract in ways that challenge precision.

Vibration and shock are often the biggest culprits. Heavy motors, presses, conveyors, and cranes generate continuous vibration that can loosen connections and degrade internal components over time. In these environments, encoders must be built not just to measure position accurately, but to survive constant abuse without drifting or failing.

Which encoder technologies perform best in harsh conditions?

The sensing technology inside an encoder makes a big difference. Optical encoders offer high resolution, but they rely on clean light paths. In dusty, oily, or humid environments, contamination can quickly compromise performance.

That’s why many manufacturers turn to inductive or magnetic encoders for harsh conditions. These technologies don’t rely on light and are far more tolerant of dirt, moisture, and vibration. They maintain reliable position feedback even when conditions would cause optical sensors to struggle. For applications in steel mills, mining, outdoor equipment, and material handling, rugged magnetic or inductive encoders often deliver the best balance of durability and accuracy.

How does vibration and shock impact encoder accuracy and lifespan?

Vibration doesn’t usually cause immediate failure. Instead, it creates subtle issues over time. Bearings wear faster, internal components shift, and signal quality degrades. The result is jittery feedback, inconsistent positioning, and eventually lost accuracy.

Shock events—like sudden stops, load impacts, or emergency braking—can accelerate this damage. Encoders designed for harsh environments are mechanically reinforced, with higher shock and vibration ratings that help preserve accuracy and extend service life. Simply put, the more rugged the encoder, the fewer calibration headaches and replacements you’ll face.

How can the right encoder reduce downtime and maintenance costs?

Downtime rarely starts with a catastrophic failure. It usually begins with small, hard-to-diagnose issues - misalignment, signal loss, or drifting position data. Choosing a rugged, industrial-grade encoder minimizes these problems from the start.

Upgrading with reliable encoders reduces unplanned shutdowns, extends maintenance intervals, and supports predictive maintenance when paired with modern control systems. Instead of reacting to failures, maintenance teams can plan interventions during scheduled downtime. Over time, this translates into lower repair costs, longer equipment life, and a healthier return on investment.

Implementing predictive maintenance strategies that leverage real-time sensor data, such as from modern encoders, can reduce unplanned downtime by 30–50% compared to traditional approaches. Predictive and condition-based maintenance programs supported by encoder and sensor data have been shown to reduce maintenance costs by 25–40%, as repairs are performed at the right time rather than reactively.

What are the key selection factors to consider?

When you’re selecting a position encoder for harsh industrial environments, a few core factors can make the difference between long-term reliability and ongoing maintenance headaches.

#1. Technology type: Magnetic encoders are a popular choice because they stand up well to dust, oil, and moisture without losing accuracy. For environments that are especially punishing—think heavy vibration, contamination, or extreme temperature swings—inductive encoders offer an even higher level of robustness while still delivering precise position feedback.

#2. Environmental protection: Encoders with IP65 protection can handle basic dust and water exposure, but many industrial applications demand more. IP67-rated devices are better suited for moisture-heavy settings, while IP69K is ideal for washdown environments where high-pressure cleaning agents are part of daily operations.

#3. Mechanical durability: Encoders with compact, rugged housings, especially stainless steel, hold up far better over time. In high-shock or high-vibration applications, bearingless designs are worth considering since they eliminate bearing wear altogether.

#4. Electrical and interface: Make sure the encoder supports the right communication protocols, such as SSI, EtherCAT, or PROFINET, and use heavy-duty, shielded cables to protect signal integrity.

#5. Absolute encoders: Absolute encoders are often the smarter choice in harsh or safety-critical environments. Because they retain position data at power-up, they eliminate risky homing sequences and help systems restart quickly and reliably.

Wrapping Up

In harsh industrial environments, choosing the right position encoder isn’t just a technical detail, it’s a reliability decision. By focusing on rugged technology, proper protection, and long-term durability, manufacturers can reduce downtime, lower maintenance costs, and keep operations running smoothly, even in the toughest conditions.